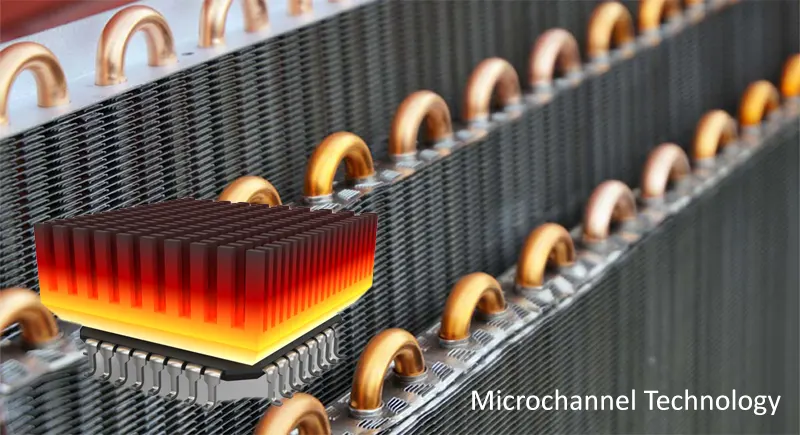

In the new era of HVAC and industrial thermal management, efficiency is not just a desire—it’s a necessity. As industries require smaller, more reliable, and more efficient systems, traditional heat exchanger designs are being put on the spot. One technology that has grown in popularity over the last few years is microchannel technology. Characterized by its high heat transfer rate and low size, this method is revolutionizing the way engineers can design heating and cooling applications across a broad range of industries.

Microchannel heat exchangers operate on a robust yet straightforward premise: by reducing the volume of fluid passages, surface area-to-volume ratios are substantially enhanced. This facilitates higher and more uniform distribution of heat at higher rates, and makes such systems optimum in applications where energy consumption and spatial constraints are limiting factors. As opposed to conventional fin-and-tube coils, which often suffer from poor flow distribution and higher weight-to-performance ratios, microchannel coils ensure uniform performance at lower material and charge of refrigerant or water.

One benefit of microchannel water coils is their ability to operate with a variety of fluids—water, glycol mixes, oils, and even proprietary coolants—without undue pressure drop. This allows them to be used for comfort cooling as well as critical temperature control in data centers, industrial processes, and commercial HVAC systems. Their corrosion-resistant construction also ensures long-term operation, especially in aggressive environments where standard copper-aluminum coils will degrade over time.

One of the most exciting uses of microchannel technology is for York replacement coils. A majority of older systems originally built with York components are in end-of-life stages or in need of retrofit to modern efficiency levels. Installation of high-performance microchannel versions of older coils offers a dramatic improvement in thermal efficiency and reduced maintenance intervals and downtime. Replacement coils are engineered to meet or surpass OEM performance, with seamless integration without compromise of system integrity.

What sets microchannel coils for retrofit use apart is the flexibility of their modular form. A rooftop unit, chiller system, or air handler specially commissioned is no different. These coils can be designed to integrate into already existing designs with few modifications. Their internal volume is similarly low, so lower quantities of fluid are required, which further means lower operating costs as well as less environmental load—a consideration of increasing importance in today’s regulatory climate.

Technologically speaking, modern microchannel coils employ advanced brazing technologies and geometrical optimization of the channels to ensure high thermal conduction. Some designs even feature enhanced surface topographies inside the channels to promote turbulence without compromising on pressure losses—a delicate art that ensures high heat transfer with efficient flow. Furthermore, the majority of units also receive protective coatings that deter moisture ingression and chemical attack, enhancing the service life even in harsh outdoor environments.

Design engineers and facilities managers are also discovering the maintenance advantages of microchannel technology. With fewer joints and connections than in traditional coil assemblies, there are fewer potential leak points. The rugged construction also reduces vulnerability to vibration-induced fatigue, a common issue in large-scale HVAC systems with constant operation.

In addition to its technical efficiency, microchannel water coils are popular also due to sustainability. With the world trying to reduce carbon emissions and refrigerant leaks, those systems that minimize fluid usage and provide the maximum rate of energy conversion are becoming standard. Microchannel technology meets these needs exactly, offering an expandable solution that is compatible with green building certifications and constricting energy codes.

In total, the optimization of heat transfer with microchannel technology is not incremental—it’s a revolution in how we think about thermal efficiency. At either new building or in replacement as York coils in installed infrastructure, these new technologies deliver significant combinations of performance, durability, and sustainability. For designers and operators who are willing to rise to the challenge of smarter heat management, microchannel water coils are no longer just a choice—its the future.